Extraction and concentration equipment

Continuous subcritical water extractor

The continuous subcritical water extractor enables extraction of raw materials such as vegetables, fruit, and tea. Subcritical water has characteristics like those of organic solvents, offering excellent component extraction and hydrolysate action. The system can therefore extract components which are difficult to dissolve in water without use of organic solvents such as acids, alkalis, or alcohol.

Pressurized/vacuum extraction tank

This tank can support both pressurized and decompressed extraction methods.

- Pressurized extraction: extraction is performed under high pressure, enhancing extraction efficiency and enabling extraction of many components

- Decompression extraction: extraction is performed under low pressure, promoting immersion into the material and enhancing extraction efficiency while inhibiting oxidation.

Atmospheric extraction tank

This tank extracts in much the same way one imagines tea being brewed in a teapot. Tea leaves are placed in a basket and immersed in hot water in the tank for a set period, after which the basket is removed, separating the tea leaves from the extract.

Press (jack)

This machine pressurizes raw materials to remove extract. The high pressure allows extract to be squeezed out.

Extraction kettles

These include both coiled and jacketed steam kettles. Different extraction kettles are used to extract vegetables, meat, and other products, depending on the intended usage and various conditions.

- Stirring kettle: for enzymatic decomposition

- Pressurized kettle: for meat extracts and other purposes

Concentrator

The type of concentrator to be used depends on the properties of the raw material and product under focus. Nikken leverages the characteristics of coil-type, plate-type, and flush-type concentrators to meet the needs at hand.

Nikken leverages our subcritical water extraction technology to fulfill OEM and consignment processing orders and welcomes such requests.

Heating/mixing/emulsifying/pulverizing equipment

Mixer

This device mixes multiple raw materials. Mixers are selected according to type and properties of the target raw material, as well as particle and lot size, to yield products fulfilling intended purposes. Mixers suitable for blending oils enable characteristic flavors which powders alone cannot express.

Extract mixing tank

This equipment heats and mixes liquid and paste materials. It can mix varying levels of viscosity and oil content and can generate a Maillard reaction* through adjustment of heating temperature and time.

*Maillard reaction: a reaction produced by heating reducing sugars and amino compounds to generate a brown substance (melanoidin)

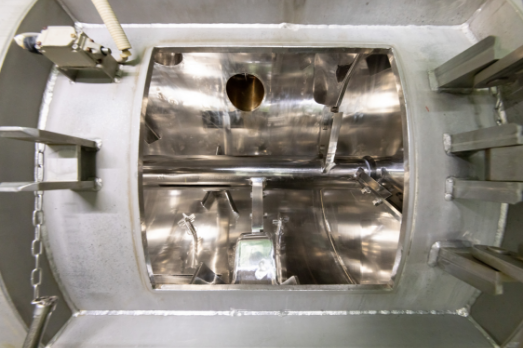

Kneader

This device enables uniform agitation without scorching even at high viscosity. Nikken also utilizes one type which concomitantly functions as a needle agitator.

Homogenizer

This device homogenizes substances in liquid. Molecules are homogenized and mixed to form a fine emulsion.

Inline mixer

This dispersing machine has coarse grinding and pulverizing functions. The fully sealed grinding and dispersing prevents intrusion of air bubbles and foreign matter.

Pulverizer

This machine pulverizes materials to fine particles.

Soup kettle

A stainless, double-layered device for simmering and warming soups and similar foods. Temperatures are maintained at sub-boiling levels to ensure food does not burn.

Vacuum oblique kneader

This machine serves a wide range of purposes, from heating to extracting, mixing, and concentrating extracts and pastes. The low-temperature heating in a vacuum enables retention of flavor, elimination of air bubbles, and production of smooth, quality products. The agitator blades have slanted rotation which enables even highly viscous raw materials to be stirred uniformly.

Direct-heat fryer

This gas-heated fryer can fry, stew, and heat over a direct flame, and is also used to produce flavored oils garnered through high-temperature extraction.

Grinder

This grinder is like a stone-mill grinder as it pulverizes materials into ultra-fine powders.

Drying/granulation

Vacuum drum dryer (VDD)

This machine performs drum drying in a vacuum. It can dry materials quickly at a low temperature.

- Dries a range of raw materials, from dilute solutions to pastes with high concentration and viscosity.

- Suitable for drying up to 100%, activating the inherent flavor and aroma and preserving original characteristics of the raw material.

- Dries quickly at low temperature, minimizing heat-generated denaturation.

- Continuous-type dryer maintains a vacuum, ensuring stable product quality.

Continuous vacuum dryer (CVD)

Liquid raw materials are continuously fed into a vacuum kettle at a constant amount, and are then heated, dried, and crushed.

- Ideal for fruit juices and materials with high sugar content as vacuum drying allows for lower temperatures than those required for ambient pressure.

- Drying at low temperature greatly minimizes material denaturation.

- When used after pre-stewing, helps preserve the roasted and cooked essence of raw materials.

- Produces a porous powder easily dissolved in either cold water or hot water.

- Can dry viscous, filled, and fibrous products.

- A continuous vacuum can be maintained, enabling stable product quality.

Spray dryer

This dryer sprays liquid into hot air as a fine mist, instantly producing a powder of spherical particles. Two methods of atomizing liquid are available: centrifugal atomization using a rotating disk and pressurized atomization using a pressure nozzle.

- Even heat-sensitive materials can be dried with minimal deterioration.

- The dried product is nearly spherical in shape and possesses excellent fluidity.

- The fine powder mixes smoothly and is easy to process for various usages.

Drum dryer

Raw materials are adhered as a film to the surface of a heated rotating drum; as the drum rotates, they undergo instant evaporative drying and are powderized.

- Extremely short drying time enables drying of heat-sensitive materials.

- Liquid raw materials can be dried as they are.

Fluidized bed granulation coating machine

This machine can granulate by spraying liquid onto fluidized powder. It can manufacture porous granules with excellent disintegration capacity and flowability, which dissolve easily.

Direct jet dryer (THERMOZONE)

Hot air from the nozzle tip is sprayed directly onto the raw material to reduce roasting time. Roasting, sterilization, and expanding yield products with special characteristics.

Band dryer

This air dryer works by blowing hot air on materials to produce dry products. Large amounts of raw materials can be processed continuously.